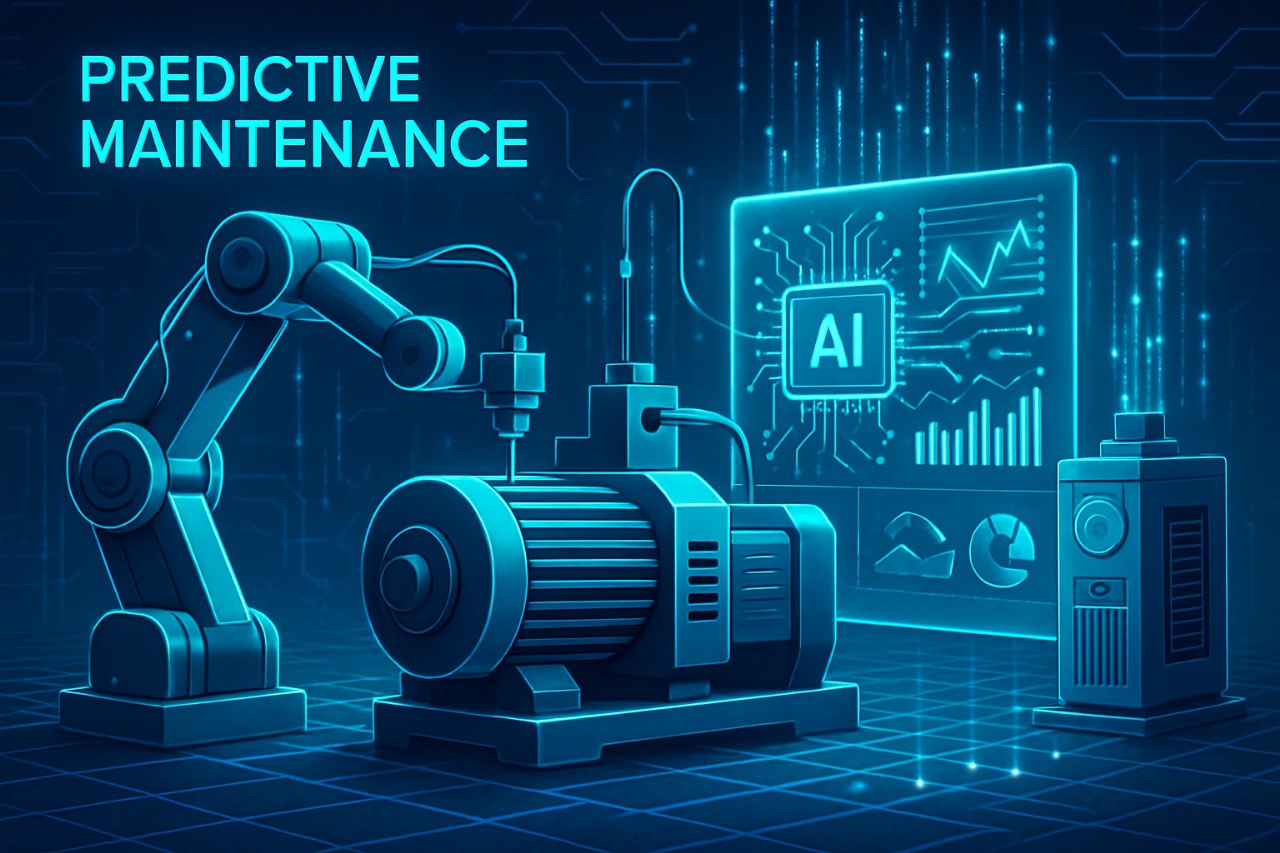

Predictive maintenance (PdM) is an advanced, data-driven strategy that enables manufacturers to anticipate equipment failures before they occur. By continuously monitoring machine health using IoT sensors and analyzing real-time data with AI and machine learning, PdM ensures maximum equipment uptime, reduces maintenance costs, and minimizes unexpected downtime. This approach extends the useful life of industrial assets while optimizing maintenance schedules for cost and resource efficiency.

Problem Overview

A rental company providing a range of reliable, high-performance heavy machinery (excavators, bulldozers, cranes, etc.) for construction projects faces significant challenges in maintaining its fleet and ensuring customer satisfaction. These challenges include:

Solution: Predictive Maintenance

Predictive maintenance addresses these challenges by moving from reactive to proactive maintenance strategies. The solution focuses on:

How It Works

Data Collection

Data Acquisition & Analysis

Proactive Decision Making

Impact

Conclusion

By adopting AI-driven predictive maintenance, rental companies gain a decisive advantage in managing their heavy equipment fleets, securing both business efficiency and customer loyalty